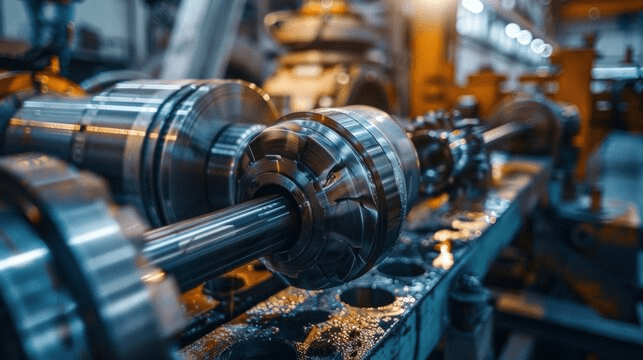

Jigs and fixtures are fundamental tools in precision parts machining, playing a critical role in ensuring the accuracy and efficiency of manufacturing processes. Jigs are custom-made tools designed to guide the cutting or drilling of a workpiece, while fixtures hold the workpiece securely in place during machining. Together, they enable consistent and repeatable production by providing precise alignment and support, reducing the risk of errors and increasing throughput. Precision parts machining, on the other hand, involves the meticulous fabrication of components to exacting standards, often using advanced CNC (computer numerical control) machines and sophisticated techniques like milling, turning, and grinding.

Don’t miss our future updates! Get Subscribed Today!

©2024. Rajaneni Precision. All Rights Reserved.